OUR INITIATIVES FOR

THE ENVIRONMENT

MANAGING PRECIOUS

WATER RESOURCES

Making clothing that doesn’t waste or pollute water

Water is one of the most precious resources on Earth. At the same time, the clothing manufacturing industry requires a lot of it. A large volume of water is required to cultivate cotton as a raw material for garments, as well as for fabric dyeing and other parts of the production process. Fast Retailing is working to identify and solve local water-related issues across all processes, from sourcing raw materials to manufacturing and retail.

Conducting regular risk assessments across our value chain

We regularly conduct risk assessments throughout the value chain using the Aqueduct water risk assessment tool developed by the World Resources Institute. As part of that process, we have evaluated our core stores and offices, as well as the garment factories and fabric mills to which we outsource our production, and have identified facilities located in high-risk areas. A follow-up survey of the stores and offices in these high-risk areas has been conducted to ascertain information about the damage caused by past flood events, and the countermeasures that are currently in place. Through these company-wide management measures, we have achieved risk reductions. Additionally, we have conducted a survey of risk-assessed factories to establish actual water conditions in surrounding areas, and fluctuations in water prices. Through this survey we have identified factories with water risks, and are now working to further support them.

Preventing and reducing water pollution to address local issues and reducing water usage

Reducing water consumption

We are cooperating with regions that face high water supply risks, and with factories that use a lot of water, on numerous initiatives to reduce water consumption. We have set specific targets for each of our garment factories and fabric mills, which account for 80% of our total water consumption. Our overall aim is to reduce water consumption by 10% per unit of water used at each factory by the end of 2025 (vs. 2020 levels).

Introducing water-saving technologies

We are working with our production partners to encourage the development and introduction of water-saving techniques. Our BLUE CYCLE technology is one such example. BLUE CYCLE uses nanobubble washing and ozone cleaning to reduce significantly the amount of water used in the washing and processing of jeans. This technology has been introduced to the manufacturing process of jeans produced and sold by all brands of the Fast Retailing group. Fast Retailing is currently promoting the use of this initiative across all brands.

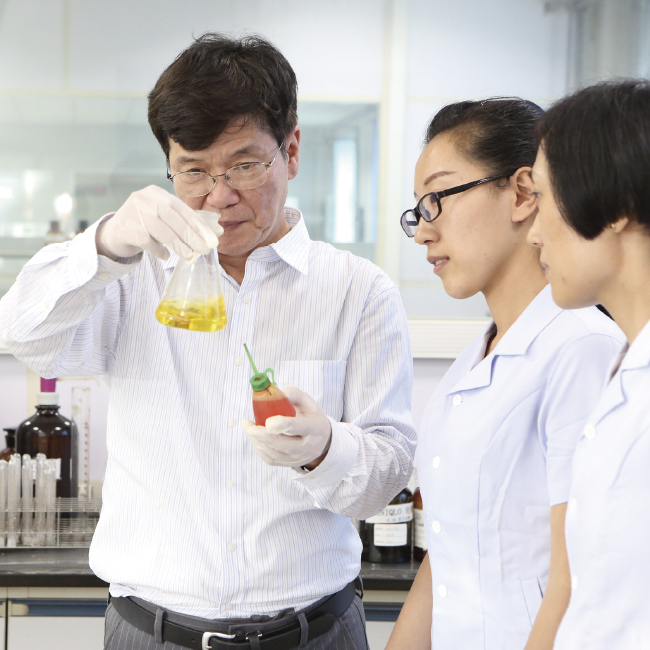

Ensuring appropriate wastewater treatment

Fast Retailing requires its core garment factories and fabric mills to conduct wastewater testing based on the Zero Discharge of Hazardous Chemicals (ZDHC) Wastewater Guidelines.(*1) Factories are then required to disclose their testing results on the Institute of Public & Environmental Affairs’ website, which is an environmental NGO based in China. If hazardous chemicals are detected in wastewater, we investigate the relevant factories and chemical manufacturers producing the offending substances to identify the root cause of any leaks. We also offer guidance to ensure that improvements are made. We aim to achieve zero pollution as determined through wastewater standards by the end of 2030.

*1 At the end of 2022, we had achieved 99% compliance with wastewater standards at our core garment factories and fabric mills.

Reducing water consumption in the production of raw materials

We seek to reduce water consumption by selecting raw materials at the product planning stage that require less water during production, and ensuring those materials are ultimately used. Furthermore, we aim to source 100% sustainable cotton across all Fast Retailing Group brands by the end of 2025. The definition of sustainable cotton includes a requirement to source cotton from areas where improvements in water usage have been made. We are also aiming to increase the proportion of recycled materials used to approximately 50% of total materials by fiscal 2030.

The definition of sustainable cottonMost Viewed Contents

-

책임있는 방식으로 조달된 솜털과 깃털

유니클로는 동물복지를 준수하며 지속가능한 방법으로 공급된 솜털과 깃털을 사용하고 있습니다.

Read More

-

리사이클 소재를 사용한 옷

리사이클 기술의 발전과 함께 리사이클 소재의 활용도 확장되고 있습니다. 유니클로 제품 라인업에서 리사이클 소재가 활용된 옷 관련한 자세한 사항은 제품의 가격 태그, 패키지, 케어라벨을 통해 확인하십시오.

Read More

-

Sustainability Report 2022

세상은 여전히 혼돈 속에 있지만, 우리는 그 안에서 새로운 기회를 발견하고 있습니다.

Read More

-

우리의 옷을 만드는 생산자들

유니클로의 옷은 전 세계 거래처 공장에서 일하는 생산자들이 함께 만들고 있습니다. 생산자 모두가 항상 웃을 수 있는 환경이 좋은 옷의 제작으로 이어집니다.

Read More

Recommended Contents

-

리사이클 소재를 사용한 옷

리사이클 기술의 발전과 함께 리사이클 소재의 활용도 확장되고 있습니다. 유니클로 제품 라인업에서 리사이클 소재가 활용된 옷 관련한 자세한 사항은 제품의 가격 태그, 패키지, 케어라벨을 통해 확인하십시오.

Read More

-

BLUE CYCLE JEANS

유니클로는 지구의 미래를 위해 지속가능한 진을 만듭니다.

Read More

-

여성 활약 지원

모든 여성들은 자유롭게 꿈꾸며 새로운 내일을 만들어 갈 수 있어야 합니다.

Read More

-

RE.UNIQLO

오래된 옷으로 더 나은 미래를 만들 수 있을까요? 유니클로는 옷을 통해 더 행복한 미래를 만들 수 있다는 믿음으로 모든 유니클로 제품에 대해 'RE.UNIQLO' 프로그램을 진행하고 있습니다.

Read More

Newest Contents

-

FIND YOUR POWER OF CLOTHING

What can we do as part of our daily lives to help our planet, our society, and our future? UNIQLO ambassadors and others are experiencing UNIQLO’s new clothes-making processes...

Read More

*영문 웹페이지로 이동합니다.

-

OUR INITIATIVES FOR THE ENVIRONMENT

UNIQLO always strives to use resources effectively and without waste, both within our own company and across our entire supply chain. We are committed not only to helping...

Read More

*영문 웹페이지로 이동합니다.

-

유니클로의 커리어 향상 프로그램 자신의 가능성을 믿고 미래로

유니클로의 중요한 파트너인 방글라데시의 봉제공장에는 약 80%의 여성 직원이 있습니다.

Read More

-

리사이클 소재를 사용한 옷

리사이클 기술의 발전과 함께 리사이클 소재의 활용도 확장되고 있습니다. 유니클로 제품 라인업에서 리사이클 소재가 활용된 옷 관련한 자세한 사항은 제품의 가격 태그, 패키지, 케어라벨을 통해 확인하십시오.

Read More